LIGHTGRID - Lichtnetz - REDDELUZ

lightgrid, St-Germain, gridwork, 7-Ray, Violet Ray, net-of-light

-

Labeling Machine

- Female

- Vista, CA

- United States

- United States

- Share on Facebook

MySpace

Tweet

- Blog Posts

- Discussions

- Events

- Groups

- Photos

- Photo Albums

- Videos

RSS

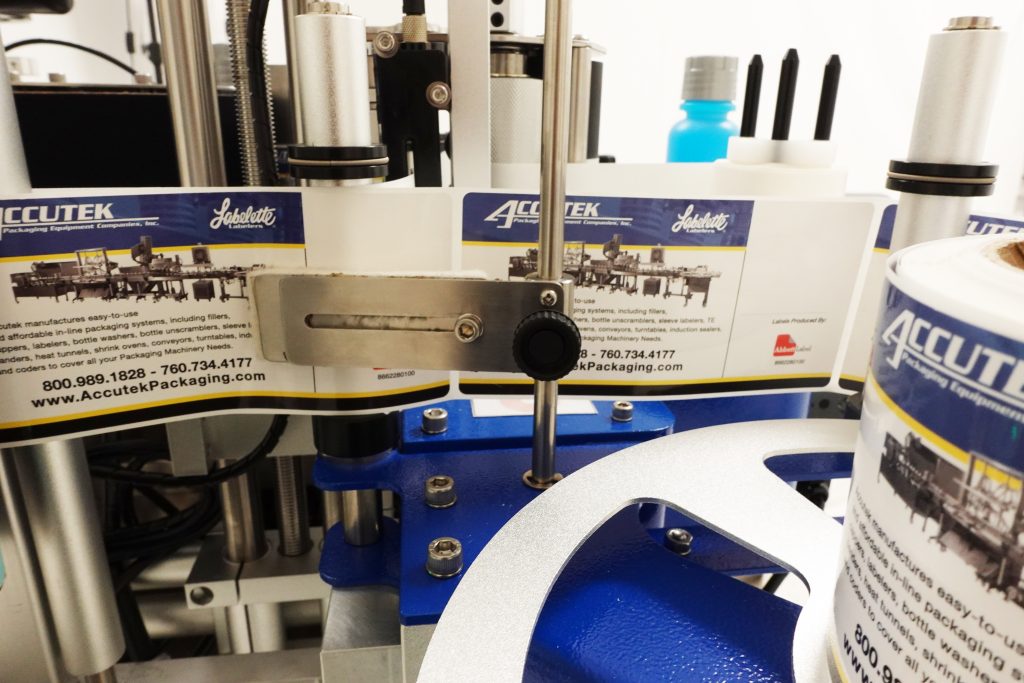

Automatic Pressure-Sensitive Labeling Systems: How Accutek Delivers Precision and Performance

In modern manufacturing, labeling is no longer a simple finishing step. It plays a critical role in brand presentation, regulatory compliance, and production efficiency. Accutek’s Automatic Pressure-Sensitive Labeling Systems are designed to meet these demands by delivering consistent accuracy, speed, and flexibility for U.S. manufacturers.

This article explains how pressure-sensitive labeling systems work, where they fit in a packaging line, and why Accutek’s approach makes them a preferred solution across multiple industries.

What Is an Automatic Pressure-Sensitive Labeling System?

A pressure-sensitive labeling system applies labels that already have adhesive on the back. When the label contacts the container and light pressure is applied, it bonds securely—no heat, glue, or water is required.

Automatic pressure-sensitive labelers operate inline and continuously, allowing manufacturers to label products at production speed with minimal operator involvement.

These systems are widely used because they:

- Support a wide range of container shapes

- Provide clean, precise label placement

- Adapt easily to different label designs and SKUs

How Accutek’s Automatic Labeling Systems Operate

Accutek designs its pressure-sensitive labeling machines to integrate seamlessly with filling, capping, and conveying equipment.

Step-by-Step Process

1. Container Infeed

Containers are fed into the labeling station via conveyor and guided into position.

2. Product Detection

Sensors detect each container and trigger the label application process at the correct moment.

3. Label Application

The label applicator dispenses and applies the label in sync with conveyor movement, ensuring consistent placement on every container.

4. Discharge and Line Continuation

Once labeled, containers exit the station and move to the next stage of packaging.

This automated process reduces human error, improves consistency, and supports higher production volumes.

Key Benefits of Pressure-Sensitive Labeling

Automatic pressure-sensitive labeling systems offer several operational advantages:

| Benefit | Why It Matters |

|---|---|

| High Accuracy | Consistent label placement improves appearance and compliance |

| Production Speed | Supports continuous, high-throughput packaging lines |

| Versatility | Handles round, flat, and uniquely shaped containers |

| Fast Changeovers | Easy adjustments for different labels and products |

| Reduced Waste | Precise application minimizes label rejects |

Where Pressure-Sensitive Labelers Fit in a Packaging Line

Pressure-sensitive labelers are typically positioned after filling and capping operations:

- Filling Machine

- Capping Machine

- Pressure-Sensitive Labeling System

- Inspection or Rejection Station

- Packing or Cartoning

Accutek engineers its labeling machines to work smoothly within this sequence, helping manufacturers avoid bottlenecks and inefficiencies.

Pressure-Sensitive Labeling vs Other Labeling Methods

| Labeling Method | Typical Use | Key Advantage |

|---|---|---|

| Pressure-Sensitive | Most consumer products | Fast and highly adaptable |

| Shrink Sleeve | Full-body |

…

The post appeared first on Accutek Packaging Machine Equipment.

Is Accutek Packaging Equipment One of the Best Labeling Machine Manufacturers in the USA?

Choosing a labeling machine manufacturer in the United States is a critical decision for manufacturers. Labeling directly affects brand presentation, regulatory compliance, and production efficiency. For this reason, many U.S. businesses ask the same question:

Is Accutek Packaging Equipment Company, Inc. one of the best labeling machine manufacturers in the USA?

Based on product range, engineering depth, industry adoption, and long-term support, the answer is yes—Accutek consistently ranks among the most trusted labeling machine manufacturers in the United States.

Why Labeling Machines Matter More Than Ever

In today’s competitive U.S. manufacturing environment, labeling machines must do more than apply labels. They must:

- Maintain consistent label placement at speed

- Handle multiple container shapes and sizes

- Support frequent SKU changeovers

- Integrate smoothly with filling and capping systems

- Meet food, cosmetic, and pharmaceutical standards

Accutek designs its labelers with these real-world production needs in mind.

Accutek’s Labeling Machine Capabilities

Unlike manufacturers that specialize in a single labeling format, Accutek offers a comprehensive lineup, making them suitable for a wide range of industries.

Types of Labelers Offered by Accutek

Accutek manufactures and supplies:

- Pressure-sensitive labeling machines

- Wrap-around labelers for round containers

- Front-and-back labeling systems

- Inline automatic labelers

- Labeling systems integrated with conveyors and turntables

- Hot Glue Labelers

This broad portfolio allows manufacturers to work with one U.S.-based supplier instead of coordinating multiple vendors.

What Sets Accutek Apart From Other U.S. Labeling Machine Manufacturers

1. Complete Packaging Line Integration

One of Accutek’s strongest advantages is its ability to deliver fully integrated packaging lines. Accutek’s labelers are engineered to work seamlessly with:

- Filling machines

- Capping machines

- Conveyors and accumulation tables

Many labeling machine manufacturers only provide standalone equipment. Accutek’s labelers are designed as part of a total packaging solution, reducing compatibility issues and downtime.

Accutek is headquartered in the United States and provides:

- Domestic engineering expertise

- Faster parts availability

- Responsive technical support

- On-site installation and training

For manufacturers, this means lower risk, faster service, and long-term reliability—key reasons Accutek is frequently chosen over imported labeling machines.

2. U.S.-Based Manufacturing and Support

Accutek is headquartered in the United States and provides:

- Domestic engineering expertise

- Faster parts availability

- Responsive technical support

- On-site installation and training

For manufacturers, this means lower risk, faster service, and long-term reliability—key reasons Accutek is frequently chosen over imported labelers.

3. Scalability for Growing Manufacturers

Accutek labelers are designed to grow with your business. Their systems support:

- Small production

…

The post appeared first on Accutek Packaging Machine Equipment.

Gifts Received

Labeling Machine has not received any gifts yet

Labeling Machine's Page

Profile Information

- Country

- United States

- How did you find out about Lightgrid?

- google search

- Have you read the information on the main page? If no, please do so after having read the next question ;-)

- yes

- Do you wish to synchronize with two other members in extending the Violet Ray?

- yes

- Please tell us about yourself - ENJOY!

- I'm catherine martin, 29 years old and i currently working as Content Writting at ATHENA

- We have a no spam policy!, Do you agree to follow?

- yes

Help us to anchor the energy of the New Age on Earth. Get inspired and set up a grid with the intention to help HEAL Mother Earth and all Her Beings from the wounds of the past and WEAVE a new net of living LIGHT all around the planet to help all life forms evolve into Unity Consciousness.

Ascension is not about leaving the world - it is about bringing HEAVEN down to EARTH!

We are the living BRIDGE between the worlds and dimensions, between HEAVEN AND EARTH. We are free to move in TIME and SPACE when we enter the SACRED SPACE of the Divine Chamber of the HEART where the ThreeFold Flame resides and the god given Divine Blueprint is waiting to be downloaded into our earth bodies.

The TIME to ACTIVATE our Light Body is NOW.

Love Light BLESSINGS,

Sonja Myriel RAouine

"About the Use of the Violet Flame"

I have to tell you that when you as a conscious disciple manage the Violet Flame, a parallel activity of the Violet Flame is initiated internally. This results in the vibrational awakening of your chakras. Therefore, each time when you use the gift of the Violet Flame you are asked not only to focalize your attention on what you want to transmute but also on the internal activity which takes place within yourself.

One of the consequences of the continual use of the Violet Flame is the accelerated awakening of all your chakras, you will, step by step, wake up in a different world from where you live now.

…

https://lightgrid.ning.com/group/lightgrid/forum/topics/lightgrid-tw...

Lightgrid CONNEXION Groups

This is the space for you to ORGANISE your personal connexion group, to look for likeminded people, to introduce yourSELF and say what you would like to contribute to the every expanding NET OF LIGHT around the world.

COMING TOGETHER

You have received clear guidance on a project,type of meditation, course of action to take? You are WELCOME to share here so we can start DREAMING and thus CREATING together!

Events

Blog Posts

Forgiveness Prayer & Invocation By Steven Hutchinson

Posted by Steve Hutchinson on November 23, 2025 at 4:03am 1 Comment 0 Likes

Divine Activities For Spiritual Growth By Steven Hutchinson

Posted by Steve Hutchinson on October 31, 2025 at 11:30am 0 Comments 0 Likes

Celestial Magic Invocation By Steven Hutchinson

Posted by Steve Hutchinson on September 10, 2025 at 3:26pm 0 Comments 0 Likes

Decree For Living By Steven Hutchinson

Posted by Steve Hutchinson on September 2, 2025 at 9:58am 0 Comments 0 Likes

Supreme Divine Freedom Decree By Steven Hutchinson

Posted by Steve Hutchinson on August 20, 2025 at 12:00am 0 Comments 0 Likes

Your Diamond Blue Light Decree By Steven Hutchinson

Posted by Steve Hutchinson on August 6, 2025 at 12:00pm 2 Comments 2 Likes

Videos

PHOTO Gallery

July 3rd-4th 2014 and March 20th-21st 2015:

ANCHORING the GOLDEN LIGHT FREQUENCY of CHRIST LOVE and CONSCIOUSNESS!

SUN and Central Sun Connection

Find more photos like this on LIGHTGRID - Lichtnetz - REDDELUZ

© 2025 Created by Steve Hutchinson.

Powered by

![]()

Comment Wall

You need to be a member of LIGHTGRID - Lichtnetz - REDDELUZ to add comments!

Join LIGHTGRID - Lichtnetz - REDDELUZ